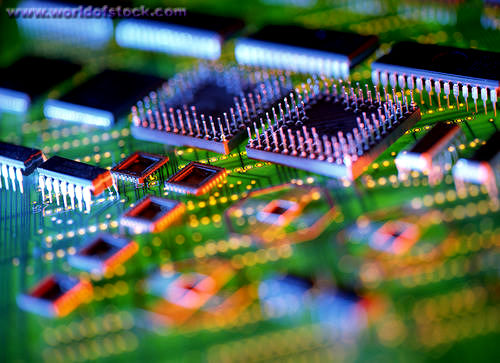

A printed circuit board (PCB), sometimes called an etched wiring board, is the base on which an electronic circuit is built. A printed circuit board mechanically supports and electrically connects many electronic components using conductive pathways or tracks. These pathways are etched from sheets of copper and then laminated onto a non-conductive substrate material. When electronic components are attached to the printed circuit board, it is then called a printed circuit assembly (PCA). Printed circuits are used in almost all commercially-produced electronic devices.

The earliest printed circuit boards were introduced in the early 20th century. Before printed circuits became popular, the less efficient and clumsier point-to-point construction was used in electronic circuits. This method has been nearly eradicated today. In early circuit boards, every electronic component had wire leads and the board had holes drilled into it for every wire of every component. These leads were passed through the drilled holes and soldered to the circuit board. This assembly method is called through-hole construction, and is now considered wasteful and expensive. More recently, the use of surface mount electronic components has become more popular due to the demand for smaller electronics, smaller packaging, and greater functionality has increased.

Electronic Components and Integrated Circuits

Surface mount electronic components differ from older components in that they are mechanically redesigned to have small metal tabs or end caps that may be soldered directly onto the surface of the printed circuit board instead of having protruding wires. This type of surface mounting allows excess electronic components to be placed on both sides of the board, which was more difficult to accomplish with through-hole construction. In turn, using both sides of the circuit board allows high circuit densities. Also, it is much easier with surface mount technology to manufacture circuit boards with an automated machine, which cuts labor costs and speeds up production.

Printed circuit boards are found in many electronic components. Often, they are used in conjunction with their smaller successor, the integrated circuit, or microchip. The integrated circuit is a much smaller circuit board that has been etched with light into a semi-conductive surface, such as silicon. These etchings are then filled with a diffusion of trace conductive elements to create a working electronic circuit. Because of their small size and singular construction, integrated circuits are very cost effective to manufacture. However, technology has not reached the point at which microchips can completely replace the printed circuit board, so the two technologies are often found side by side in the same electronic device.